Continuing Berkeley’s legacy in forest products

Cooperative Extension professors Daniel Sanchez and Paul Mayencourt build on the University of California Forest Products Lab’s 50-year history through their research on innovative, low-carbon wood products.

This story is part of a series commemorating 50 years of the College of Natural Resources at UC Berkeley. Read more about our history, fun facts, and other points of pride in our special issue of Breakthroughs magazine or on our 50th anniversary page.

When the University of California Forest Products Laboratory opened its doors at the Richmond Field Station a few miles north of the UC Berkeley campus in 1955, leaders within the California state government hoped the new facility would provide a centralized hub for research on wood products and processing.

[image caption]

Before then, research in wood technology and forest products occurred at various UC Berkeley locations. From 1903 to 1909, the College of Engineering operated a timber testing laboratory in partnership with the U.S. Forest Service (then the Bureau of Forestry). The Forest Service operated a research kiln in the Berkeley Hills for a few years beginning in 1911. Most notably, the University introduced its undergraduate forestry degree in 1914—a program that has evolved and expanded over the past 110 years.

In the 1940s, lawmakers in California and across the U.S. began investing in laboratories and facilities dedicated to developing next-generation wood products and technologies to further capitalize on wartime developments. By 1953, the California legislature approved the creation of the Forest Products Lab and allocated $1 million in startup funds.

Fred Dickinson, who previously led the Department of Wood Technology at the University of Michigan, was recruited to the UC Berkeley faculty in 1955 as a professor of forestry and inaugural director of the Forest Products Lab. He led the Lab for its first 25 years, building up a research and teaching program that would continue for roughly 50 years. Today, the Lab’s legacy lives on through the efforts of Rausser College researchers who are exploring new and innovative applications of wood products to help California meet its climate and carbon sequestration goals.

Early years

In a history recounting the Forest Products Lab’s first 25 years, Dickinson wrote that he sought to create an “institute concerned with mission-oriented research,…basic and applied investigations,…and educational activities at the graduate and undergraduate levels.” University of California President Robert Gordon Sproul appointed a technical advisory board of industry representatives to help inform the Lab’s activities and operations.

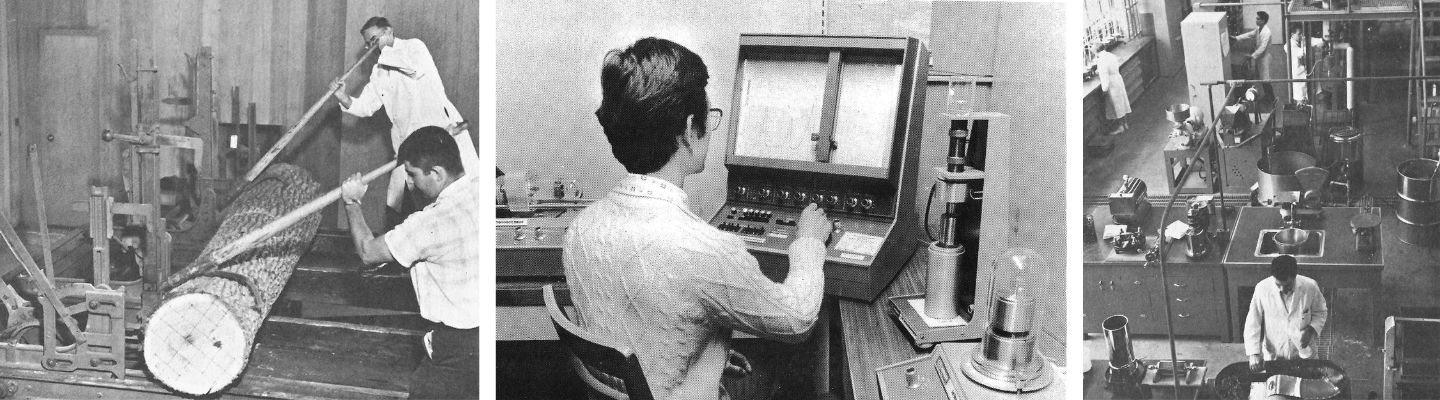

[image caption]

At its onset, the Lab provided space for students and faculty to explore novel and commercial research relating to the biology, chemistry, and physics of wood. Dickinson purchased a circular sawmill, three dry kilns, low- and high-pressure boilers, and conventional wood shop equipment like a joiner and table saw with the funding approved by the state. Arthur Anderson, a biochemist and lecturer in the School of Forestry and Conservation, was appointed head of the Division of Wood Products Chemistry as Dickinson continued to recruit faculty and support staff. The Lab established a dedicated library and introduced a master’s degree in Wood Technology in 1956, hired William A. Dost as its first Cooperative Extension specialist in 1962, and welcomed its first PhD students in 1964.

According to Dickson, the Lab had recruited enough faculty and assistants by the late 1970s to allow their teaching and research programs to “...evolve considerably, but with a continued recognition of the importance of the Laboratory to the State’s forest products industries.” Robert A. Cockrell and Arno P. Schniewind led inquiries into the technical and mechanical properties of California’s native hardwoods. Eugene Zavarin and David L. Brink worked alongside Anderson on chemical studies of several tree species and processing techniques. W. Wayne Wilcox focused on increasing the efficiency of California’s timber harvest by investigating the influence of biological factors like decay and bacteria. Dickinson retired in 1980 after 25 years as the Lab’s director. Forestry professor Donald G. Arganbright succeeded him, serving as director until 1986.

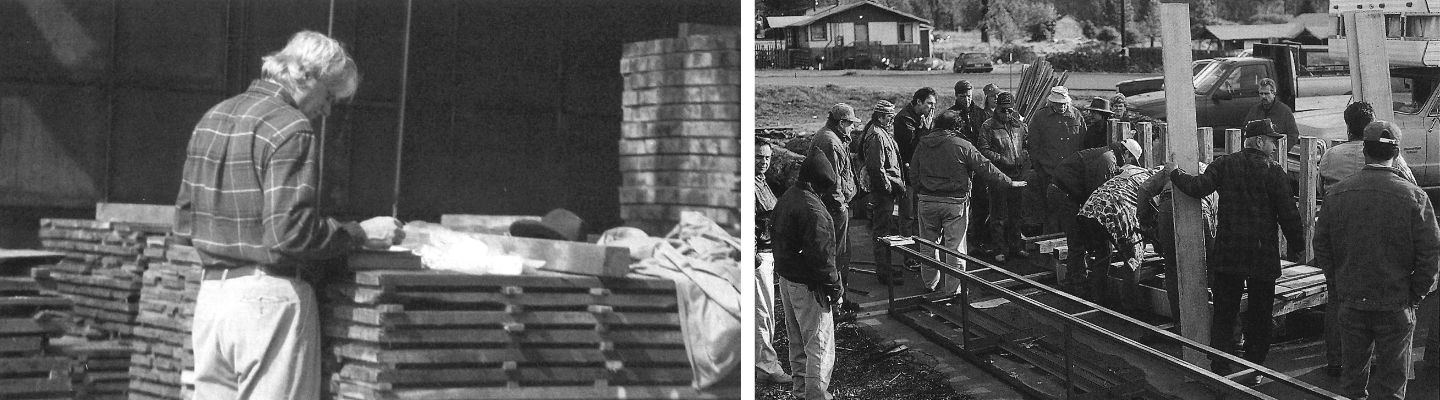

[image caption]

The university recruited Wood Science professor Frank Beall to lead the Lab two years after Arganbright's departure. As director, Beall initially pursued research programs on building materials and woody biomass, the byproducts created during the management of forest, woodland, or rangeland environments. Three research centers focused on structural pests, nondestructive evaluation (NDE) of wood and wood-based materials, and service to industry were created to support outreach efforts.

Changes and transitions

In July 1995, program administration was transferred from the College of Natural Resources to the statewide Division of Agriculture and Natural Resources (UCANR). Doing so expanded the Lab’s footprint from a UC Berkeley research center to a statewide program linking research across the University of California system. Beall hired John Shelly, MS ’77 PhD ’88 Wood Science and Technology, as a Cooperative Extension advisor and worked with UCANR leaders to shift its focus to four new areas: wood durability, fire performance, nondestructive evaluation (NDE) of wood and wood-based materials, and utilization of woody biomass. “This is a departure from our former and broader two-program emphasis. Each of the four programs interlink strongly with several others,” Beall wrote in a 1999 annual report.

By 2001, the Lab was able to hire two additional Cooperative Extension advisors—home fire-protection expert Stephen Quarles and retired Forest Service deputy director Kenneth S. Blonski—but retirements and separations jeopardized its long-term future. Wilcox left that summer, leaving Beall as the sole faculty member in Wood Science and Technology. The Lab closed in 2004, and UC Berkeley discontinued the Wood Science and Technology graduate program shortly after. Over 100 graduate students completed their master’s and doctorate degrees during the program’s run.

[image caption]

Quarles and Shelly continued their research and outreach through UCANR’s Woody Biomass Utilization Group, which was created in 2005 as an outgrowth of the Forest Products Lab. With support from state and federal partners, the research group began to study new technologies and processes capable of turning diseased, dying, and small-diameter trees—things that would otherwise burn during fires or decay during forest management treatments—into fuel, structural and non-structural wood products, and lumber.

A new focus

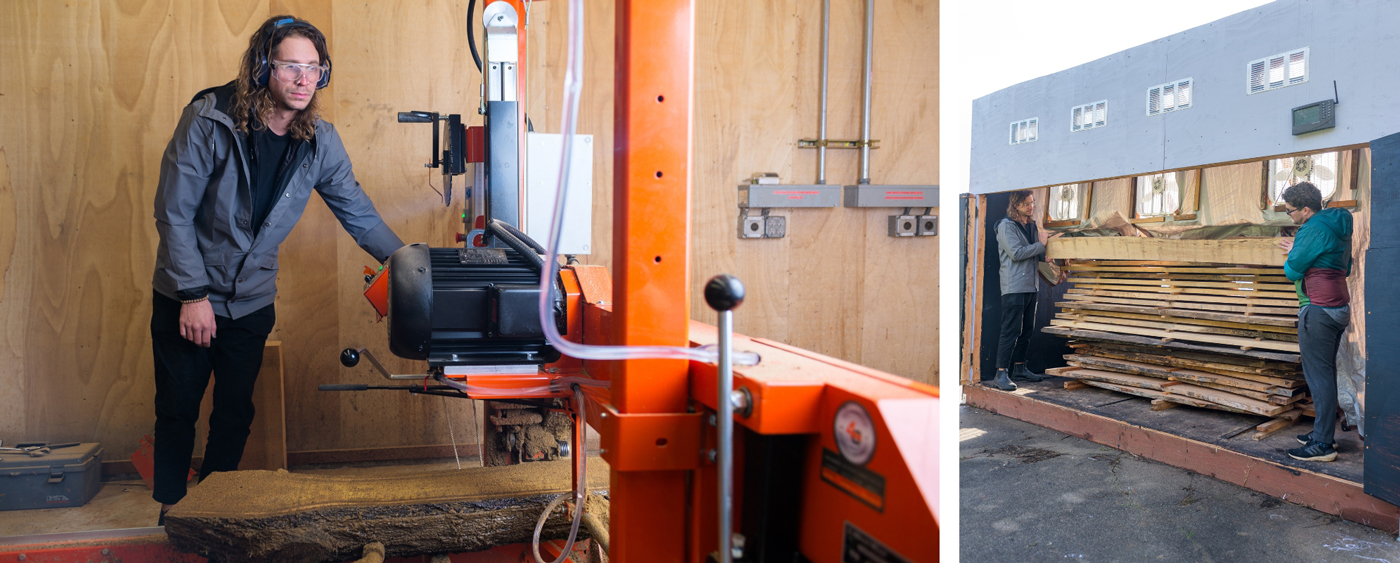

[image caption]

Daniel Sanchez (PhD ’15 Energy and Resources Group), who has studied the intersection of bioenergy, climate policy, and carbon capture and sequestration for the last decade, notes that “there has been a renewed interest in exploring innovative wood products and their interface with forest management and fire risk reduction in the state of California.” He joined the College in 2018 as an assistant professor of Cooperative Extension focused on woody biomass utilization and now directs the Carbon Removal Lab, which continues some of the research conducted at the former Forest Products Lab.

Much of Sanchez’s research is dedicated to scaling and commercializing various technologies and products that remove carbon dioxide from the atmosphere. He also conducts outreach efforts geared toward policymakers and technologists to help encourage the adoption of these new approaches. In the past few years, Sanchez has begun exploring how low-value and waste biomass from forests and lumber production could be utilized elsewhere. To further that work, Sanchez helped recruit Paul Mayencourt, an expert on engineered and structural wood products, as an assistant professor of Cooperative Extension in the Departments of Environmental Science, Policy, and Management and Architecture.

[image caption]

A former postdoctoral researcher in the Carbon Removal Lab, Mayencourt’s research merges the fields of structural design, forestry, and materials to explore low-carbon approaches for building structures by leveraging recent advances in manufacturing technologies and computational optimization. Together, Sanchez and Mayencourt have worked to clear out and revitalize former Forest Product Lab facilities, turning them into “a space where we can take any trees and turn them into wood products used for architecture or build scale demonstrations,” said Mayencourt

The pair have since acquired a portable sawmill, designed and built a kiln that can dry wood using solar power, and repurposed existing equipment to run a wood fabrication shop. They are currently testing engineered mass timber products, created when layers of wood are fixed together using adhesive or non-adhesive joiners (like dowels), for use in residential and commercial construction projects. “There is a lot of interest in mass timber because it’s a good material for sustainable and low-carbon buildings,” Mayencourt said, noting that these components can be easily fabricated from small-diameter softwood trees and native California hardwoods like tanoak—which rarely make it to commercial sawmills and are often left to rot or burn in forests. “We’ve built some proofs of concept for companies and hope to see these ideas make their way into the industry.”

[image caption]

Sanchez and Mayencourt also leverage new technical and computational tools to reevaluate existing manufacturing processes to determine whether they can be improved or modified. They are currently working with the California Department of Forestry and Fire Protection (CAL FIRE) on a grant-funded project to explore a new method of producing wood veneers that is cheaper and recovers more material. They plan to hire a full-time staff member to lead fabrication within the wood shop as they grow their research program and hope to host an architect and graduate student researchers as well.

Read More

- Trunk to Table: Forest Stewardship visits the modernized UC Wood Products Lab at the Richmond Field Station (UCANR)

- Cooperative Extension Specialists: Incubating Climate Change Solutions (Breakthroughs magazine)

- Forest to frame: Paul Mayencourt bridges forest management and sustainable construction (College of Environmental Design)